RESCOLL is a French SME. We offer metallization (coating) and repair of metallic and composite parts. We work with SMEs as well as with the largest industrial groups to offer metallization techniques responding to many problems. In collaboration with our local partners, we produce both unit parts and large series..

Cold Spray is a technique of impact material deposition, at the crossroads of thermal spraying and additive manufacturing.

Electric Wire Arc Spray is a thermal process, generally used for its excellent ability to produce anticorrosive coatings, as well as for the repair by reloading of metal parts.

These processes open up many possibilities in the fields of repair, maintenance, and manufacture of mechanical parts and subassemblies. We bring the right metal in the right place, without mechanically or thermally altering the treated parts.

MECHANICAL INDUSTRIES NEW ENERGIES AÉROSPATIAL

Cold Spray technology opens up new possibilities for a wide range of applications:

Endowed with powerful means and a passionate team, KOMETA TECHNOLOGIES answers to your problems by proposing:

- case studies, leading to innovative solutions, consistent with your requirements,

- research & development to find and develop the right solution for your needs, a deployment in industrial mode, flexible and optimized by our means of production,

- custom manufacturing.

KOMETA TECHNOLOGIES relies on its partners University, Laboratories, Subcontractors to offer global solutions that can be integrated into a production line.

The COLD SPRAY process, robotic application for very high quality metal deposits (adhesion, density, precision). We use a PLASMA GIKEN PCS 1000 system identical to the video below.

Promotion video PLASMA GIKEN

The ELECTRIC WIRE ARC SPRAY process, manual or robotic application for metallization and reloading (zinc, aluminum, nickel, stainless steel, hard facing …). We adapt our thermal spraying processes to the coatings to be produced.

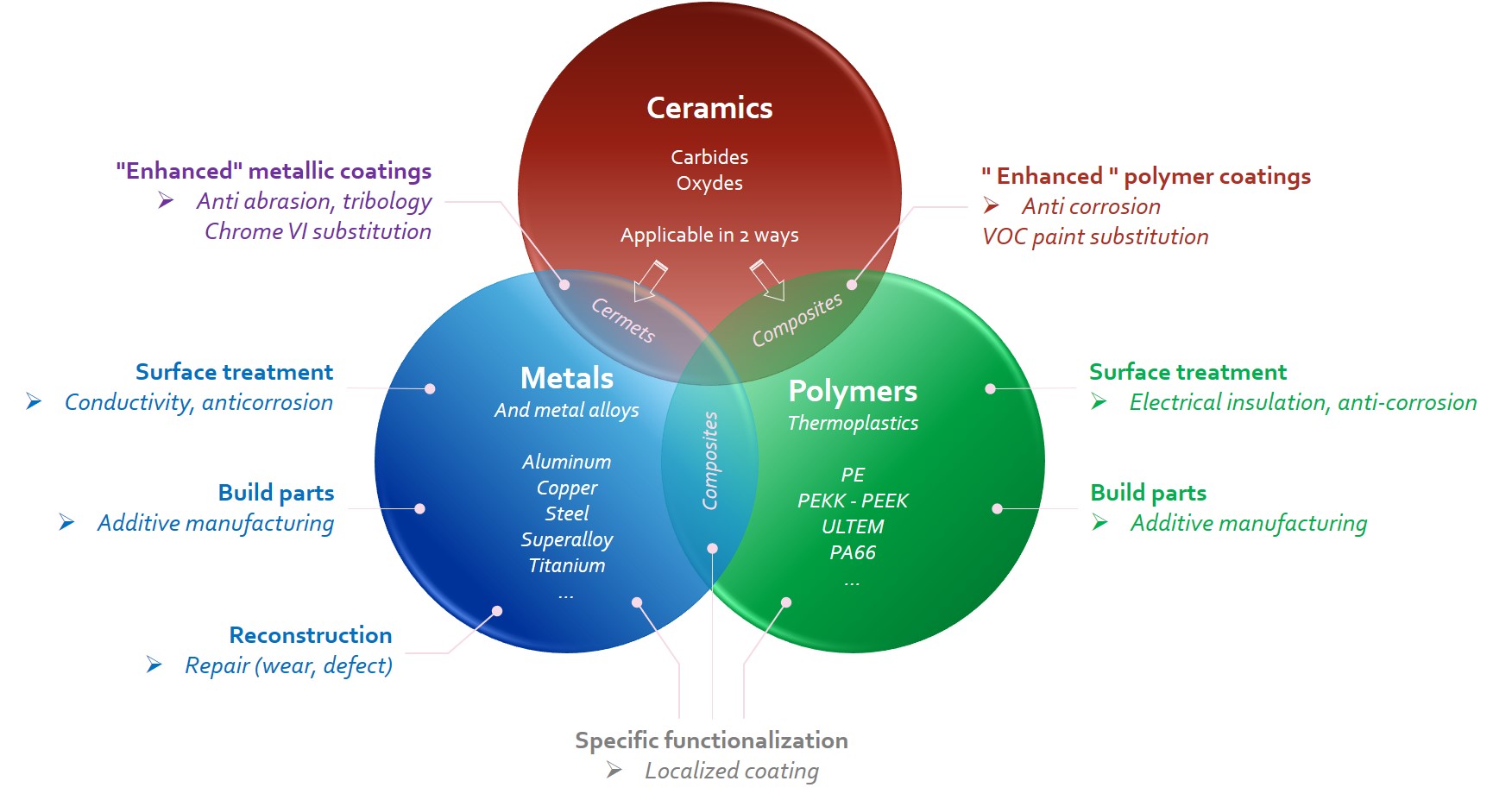

According to your requirements, we select together the best coating capable of satisfying your application. The possibilities are very numerous, we collaborate with several producers of filler material (powder or wire) to regularly offer new coatings.

KOMETA TECHNOLOGIES already works with many customers in a wide variety of business sectors, do not hesitate to contact us, we certainly have the coating you are looking for !!

More videos on youtube